Shelving.com

-

6' Standard Duty Single Sided Cantilever Rack w/ 12" Arms - Starter Unit

Starting at $796.31 -

6' Standard Duty Single Sided Cantilever Rack w/ 12" Arms - Add-On Unit

Starting at $427.86 -

6' Standard Duty Double Sided Cantilever Rack w/ 12" Arms - Starter Unit

Starting at $1,103.69 -

6' Standard Duty Double Sided Cantilever Rack w/ 12" Arms - Add-On Unit

Starting at $581.55 -

6' Standard Duty Single Sided Cantilever Rack w/ 18" Arms - Starter Unit

Starting at $826.37 -

6' Standard Duty Single Sided Cantilever Rack w/ 18" Arms - Add-On Unit

Starting at $442.89 -

6' Standard Duty Double Sided Cantilever Rack w/ 18" Arms - Starter Unit

Starting at $1,163.81 -

6' Standard Duty Double Sided Cantilever Rack w/ 18" Arms - Add-On Unit

Starting at $611.61 -

6' Standard Duty Single Sided Cantilever Rack w/ 24" Arms - Starter Unit

Starting at $852.35 -

6' Standard Duty Single Sided Cantilever Rack w/ 24" Arms - Add-On Unit

Starting at $455.88 -

6' Standard Duty Double Sided Cantilever Rack w/ 24" Arms - Starter Unit

Starting at $1,215.77 -

6' Standard Duty Double Sided Cantilever Rack w/ 24" Arms - Add-On Unit

Starting at $637.59 -

6' Standard Duty Single Sided Cantilever Rack w/ 30" Arms - Starter Unit

Starting at $943.71 -

6' Standard Duty Single Sided Cantilever Rack w/ 30" Arms - Add-On Unit

Starting at $501.56 -

6' Standard Duty Double Sided Cantilever Rack w/ 30" Arms - Starter Unit

Starting at $1,397.73 -

6' Standard Duty Double Sided Cantilever Rack w/ 30" Arms - Add-On Unit

Starting at $728.57 -

6' Standard Duty Single Sided Cantilever Rack w/ 36" Arms - Starter Unit

Starting at $962.49 -

6' Standard Duty Single Sided Cantilever Rack w/ 36" Arms - Add-On Unit

Starting at $510.95 -

6' Standard Duty Double Sided Cantilever Rack w/ 36" Arms - Starter Unit

Starting at $1,435.29 -

6' Standard Duty Double Sided Cantilever Rack w/ 36" Arms - Add-On Unit

Starting at $747.35 -

6' Standard Duty Single Sided Cantilever Rack w/ 42" Arms - Starter Unit

Starting at $1,073.11 -

6' Standard Duty Single Sided Cantilever Rack w/ 42" Arms - Add-On Unit

Starting at $566.26 -

6' Standard Duty Double Sided Cantilever Rack w/ 42" Arms - Starter Unit

Starting at $1,670.69 -

6' Standard Duty Double Sided Cantilever Rack w/ 42" Arms - Add-On Unit

Starting at $865.05

Featured Categories

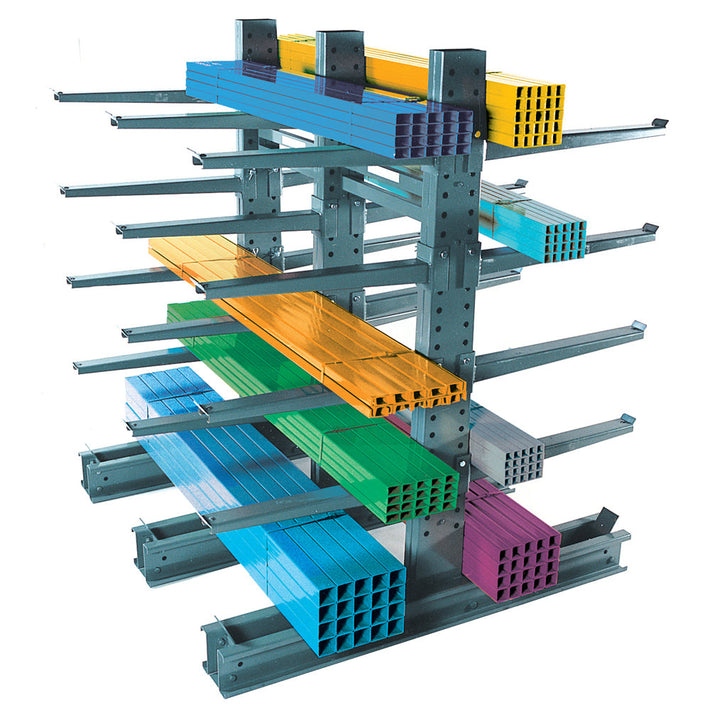

Collection: Cantilever Racks

Furniture Racks, Pipe Racks & Lumber Racks are all part of Cantilever Racking, which is a great solution for storage of long & bulky materials. Cantilever Uprights, Arms and Brace Sets now available! Call Us

What is a Cantilever Rack?

Cantilever Racks are comprised of three components:

These components must be ordered in the appropriate quantities and capacities.

Cantilever Rack is the ideal system for storing furniture, steel bars, pipe and tubing, lumber and other long, heavy items that must be kept off the floor...provides instant accessibility to one piece or a full load. Forklift easily loads off and on arms and bases. Being modular in nature, additional arms, uprights and braces may be added as storage requirements change.

Cantilever Uprights

Uprights consist of a vertical column and a horizontal base which is bolted to a column. A minimum of two uprights must be ordered to form a storage bay. Each edge of the column is punched vertically on 3" centers so it may be used as a single or double sided upright depending on the size of the base used.

Holes are provided in the base to anchor the upright to the floor. Uprights must never be attached to walls, columns or other structures.

Cantilever Arms

Cantilever arms are the heart of the rack system. Proper selection can make or break a successful storage plan. Shelving.com offers straight arms (generally used for storing stable loads such as lumber, steel sheets, cartons and skids) and inclined arms (for cylindrical objects or loads that tend to roll forward). Arms can be adjusted on 3" centers up and down the upright and are available in lengths to 60" in a variety of capacities. Standard arm color is gray.

Straight Arm

Straight arms up to 48" long have a minimum pitch of 3/8" per foot to compensate for deflection. 54" and 60" arms have a minimum pitch of 5/8" per foot.

Inclined Arm

Inclined arms have a pitch of 20 degrees or approximately 4.36" per foot.

Hair Pin Keeper

The hair pin keeper permits instant adjustability and is easily inserted and removed for adjustment of arm height. Lips are available on all arms.

Brace Sets

"2B" Horizontal Brace Pattern

Used on 6' to 10' Medium duty uprights and 8' Heavy duty and Series 2000 uprights.

"3B" Horizontal Brace Pattern

Used on 12' Medium duty uprights and Series 2000 uprights and 12' x 14' X Series upright.

"4BX" Horizontal Brace Pattern

Used on 15' to 20' Heavy duty and X Series uprights and all structural cantilever rack.

"4BXX" Horizontal Brace Pattern

Used on all 15' to 20' uprights when the brace length exceeds 84" centerline to centerline of upright.

Designing a Cantilever Rack System

The key to a successful cantilever rack system is the answer to one question: What is the product (load) being stored? The answer must include the length, depth, height and weight of the product. Once this data is ascertained it becomes a simple matter to determine the required arms, uprights and braces.

Determine the number and spacing of arms

The load must be supported by enough arms to prevent load deflection. Deflection may cause damage to the load being stored as well as the arms (figure A1). To detect deflection, place the load over two wooden blocks (to represent cantilever arms) as shown in figure A2. If deflection is not present it is acceptable to use a two are system as long as this does not create an overload condition. If the load shows deflection use three blocks as shown in figure A3 or four blocks as in figure A4.

IMPORTANT: The load should overhang the end arms by one-half the distance from upright centerline to upright centerline. Failure to observe this measure may cause an overload condition on the arms.

Determine the length of the arms

The depth of the load should never exceed the length of the arm. A 48" wide bundle of plywood requires a 48" long arm, bundles of steel 24" wide require a 24" arm and so on. Rated arm capacities may be seriously diminished if proper loading techniques are not observed. Figures B1, B2 and B3 illustrate correct and incorrect arm loading.

Determine the height of the upright

When determining the height of the upright it is important to consider the ceiling height, forklift reach, sprinkler systems and other factors, such as local building codes, that might effect the overall height.

The height of the upright in figure C1 is determined by adding the base height, the number of loads to be stored, the arm thickness plus 6" clearance between the load and next arm. Contact your Shelving sales professional for various rack dimensions such as base height and arm thickness.

IMPORTANT: the load placed on the base does not diminish the rated capacity of the upright. Thus, the heaviest loads should be placed on the base.

Determine arm and upright capacities

As previously discussed, each arm supports an equal amount of the load's weight. By determining the number of arms per level and dividing it into the weight per level, the required arm capacity can be determined (see example at right).

To determine the required capacity of each upright, multiply the number of arms per side by the load on each arm. In figure D1, each arm holds 2500 lbs. Twelve arms per side times 2500 lbs. per arm equals 30,000 lbs., which when divided by three uprights, results in a required minimum capacity of 10,000 lbs. per upright.

Note: Total arm capacity must never exceed total upright capacity.

Determine brace length

Brace length is defined as the horizontal distance from centerline of upright to centerline of the next upright.

Cantilever Racks

Cantilever racks consist of three components: uprights, arms and brace sets. Cantilever racks are ideal for storing bulky materials such as furniture, steel bars, pipe, and tubing. Not only do our cantilever storage racks provide smart storage, but also instant accessibility to materials. Cantilever racks can be changed and adjusted when needed, making them extremely versatile. Discover a better storage solution for your storage facility with cantilever racks.

Cantilever Uprights

Give your storage system the vertical height its' been needing with sturdy cantilever uprights. Cantilever uprights are sturdy and made to stay put; these uprights feature holes that the cantilever arms attach to. Uprights consist of a vertical column and a horizontal base which is bolted to a column. Build your ultimate storage system starting with cantilever uprights.

Cantilever Arms

It wouldn’t be cantilever racking without heavy duty, stable cantilever arms. The cantilever arms are the heart of the rack system. Having the proper cantilever arms is essential for the very best cantilever rack storage system. Shelving Inc. offers three different types of cantilever arms. You can choose from straight arms, inclined arms, or hair pin keepers. All our cantilever arms can easily be adjusted to store your materials best.

Cantilever Brace Sets

Cantilever brace sets are the last and final piece you will add to assemble your cantilever racking system. Make sure your brace sets for the length and width of your chosen cantilever arms for the correct support performance, and ensure your cantilever rack storage system can handle your stored materials with cantilever brace sets. Shelving Inc. is here to solve all of your storage dilemmas.

Let Us Install For You

We don’t just sell stellar shelves. We design custom organized spaces that fit your needs, large or small.

We Can Help YouLet Us Install For You

We don’t just sell stellar shelves. We design custom organized spaces that fit your needs, large or small.

We Can Help You